QA Recipes for a Successful Automated Inventory Management Tool

by Sofiia Hrynevych | September 28, 2022 9:36 am

Current economic trends make businesses look for options to save resources and eliminate time-consuming procedures. According to Gartner’s 2021 survey[1], 89% of respondents revealed plans to invest in order to increase the agility of their supply chains over the next two years, and 87% expressed determination to make them more resilient in the face of new challenges.

For distributors and manufacturers, achieving these goals depends on having an effective inventory management system. These tools help to easily keep track of items available in stock, monitor their shelf life, and make well-informed decisions. Small businesses may still rely on a manual inventory system, which presupposes physical counts and regular manual updates of stock levels. However, bigger enterprises that need to manage multiple items, and sell them via different channels, choose to automate this process and use cutting-edge solutions.

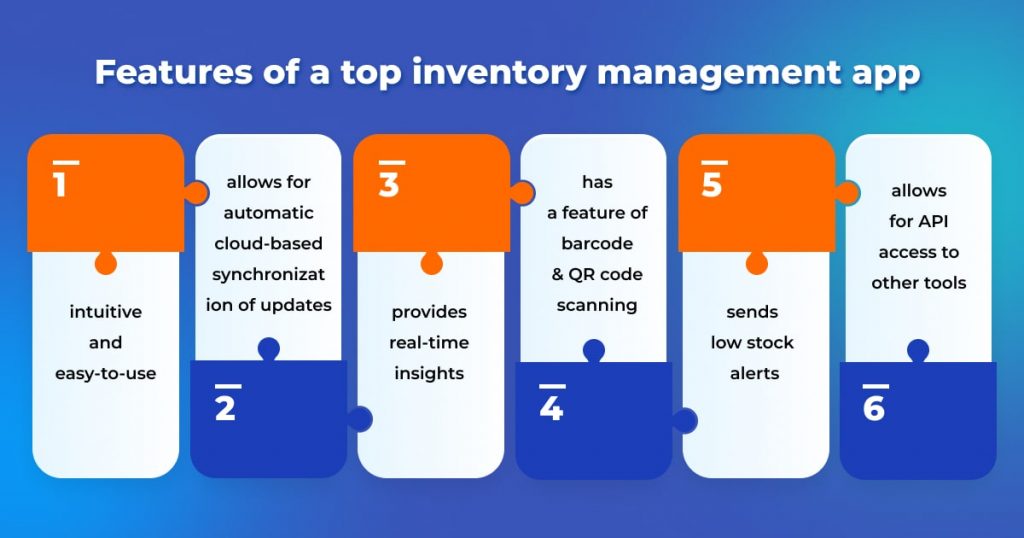

We have analyzed the top applications for automated inventory management and found several common features that we can’t wait to share with you. In addition, our experienced QA engineers have provided us with a list of key aspects to check before releasing such software, and we will also reveal it later in our article. So let’s jump right in!

What do the most successful inventory management apps have in common?

Intuitive UI

One of the very few drawbacks of automated inventory management tools is that sometimes they can be too complicated to get the hang of and require long-lasting training. This is why it is important that the product’s UI is simple and that incorporating this new system does not cause significant delays in the operations of an enterprise.

Automatic cloud-based synchronization of updates

This is an amazing feature that allows any member of a team to see accurate information about the updates made by other employees. A person can make changes to inventory data from their device, and others will be aware, so the team stays in sync.

Real-time insights generation

One more common feature of the best inventory management apps is that they give their users the ability to crunch accurate numbers and have real-time data on their stock. This also includes the option to generate insightful reports to re-order supplies and schedule other activities for the future.

In-app barcode & QR code scanner

This function enables users to save a ton of manual effort while receiving a new batch of inventory, for example. They just have to scan the barcode or a QR code on new items, and their quantities will be automatically updated in the system. In addition, an employee can use this scanner to get instant access to full information on a given inventory item, like its status, cost, availability, location, etc.

Alerting on low stock

Another crucial feature of inventory management software. Stock-outs and overstocks can cause considerable damage to distributors and manufacturers, so avoiding these issues is the first and foremost goal of adopting a tool for inventory tracking. However, the developers of top apps went further. They enhanced their software’s functionality with an option to send scheduled alerts to notify about the need for maintenance or repairs of some inventory. Moreover, it is also a great idea to include a function of e-mail alerts in case an employee responsible for restocking is not using a device with an app on it at that moment.

API access to other tools

The leaders among inventory management app creators also ensure that their software integrates with already existing systems and tools of a company. For example, API integration with a manufacturer’s online store or other e-commerce platforms, where its products are sold. This feature gives the software the ability to track and import orders from other channels to a unified system and sync inventory levels, so the customers have accurate information on the availability of products.

Useful tips on testing inventory management apps

Modern software for automated inventory management is quite complex as it gives access to extensive functionality, has to perform seamlessly on different devices (PCs, smartphones, tablets), and, ideally, should be integrated with other systems. Since such apps help their users to monitor a whole chain of processes, a defect in either of the ‘links’ can be detrimental to both budget and reputation of a company.

This is why performing rigorous testing before releasing such software products is always a must. Here are a few things that require close attention while checking these solutions:

Secure access. A QA team working on verifying inventory management systems has to come up with test cases to check that access to inventory data can’t be shared with a person outside of a particular organization.

Test documentation. Since inventory management software is multi-functional and consists of different subsystems, it is important to support the testing process with detailed and accurate documentation[2]. It will not only facilitate the work of QA engineers that are already involved in the project but will also help with onboarding new specialists.

Usability testing. The market of applications for inventory tracking is quite competitive, and many businesses make their decision to adopt a new solution based on its usability[3]. A user-friendly application requires not only checking the accessibility of its interface elements but also its navigation logic. For such complicated products as inventory management systems, we also recommend testing the training materials provided along with them to ensure quick user adaptation.

Executing real-life scenarios. This aspect is crucial for the functional testing of this software. Examples of such scenarios can be creating and receiving different types of supply chain documentation in the app (bills of materials, goods receipts, goods issue notes, goods inspection notes), returning items via e-store, using different units of measurement, etc.

Implementing test automation. For complex software products with functionality that can be frequently updated, it is always better to strike a balance between manual and automation testing[4]. Setting up autotests for repetitive checks will save significant time and costs for future releases.

API testing. If your inventory management software includes the option of API integration with other tools, like accounting applications or marketplaces, it is necessary to set up an API test environment and check this function.

In the case of automated inventory management systems, the earlier you begin testing activities, the lower the risk of finding critical bugs before the market release. However, due to our relevant experience in the field, the team of QATestLab can be involved at any stage of the development process and provide you with targeted QA solutions for your specific project.

Even if your software is complex by nature, it is possible to make it a piece of cake for your end-users. Don’t hesitate to contact us, and we will be happy to discuss your requirements and provide you with a variety of testing options.

Learn more from QATestLab

Related Posts:

- Gartner’s 2021 survey: https://www.gartner.com/en/newsroom/2021-02-10-gartner-survey-finds-87-of-supply-chain-professionals-plan-to-invest-in-resilience-within-the-next-2-years

- documentation: https://qatestlab.com/services/test-documentation/?utm_source=blog&utm_medium=article&utm_campaign=inventory-management-testing-28092022

- usability: https://qatestlab.com/services/manual-testing/ux-usability-testing/?utm_source=blog&utm_medium=article&utm_campaign=inventory-management-testing-28092022

- balance between manual and automation testing: https://qatestlab.com/is-your-project-ready-for-test-automation/?utm_source=blog&utm_medium=article&utm_campaign=inventory-management-testing-28092022

- When Bugs Tank Your Rankings: How QA Testing Drives SEO Performance: https://blog.qatestlab.com/2026/02/11/when-bugs-tank-your-rankings-how-qa-testing-drives-seo-performance/

- ICE Barcelona 2026: Between Poker Wins and Talks on QA in iGaming: https://blog.qatestlab.com/2026/02/03/ice-barcelona-2026-between-poker-wins-and-talks-on-qa-in-igaming/

- The 2025 Cloudflare Outage: A Stress Test for SaaS Resilience: https://blog.qatestlab.com/2025/12/16/the-2025-cloudflare-outage-a-stress-test-for-saas-resilience/

Source URL: https://blog.qatestlab.com/2022/09/28/inventory-management-testing/