- QATestLab Blog >

- End-to-End Testing >

- End-to-End Testing in Logistics: Why It Matters and How to Do It Right

End-to-End Testing in Logistics: Why It Matters and How to Do It Right

Logistics software has become the backbone of global supply chains. From order placement to final delivery, every interaction depends on systems that must work seamlessly together. A single error in routing or a failed API call can cause delays, financial loss, or frustrated customers.

Over the years, working in a top testing company, I’ve seen how these small technical details often translate into very real business consequences. End-to-end testing helps expose these risks early and proves that logistics platforms are ready for real-world conditions.

With that perspective, let’s examine what end-to-end testing means in logistics and which areas deserve the most attention.

What End-to-End Testing Means in Logistics

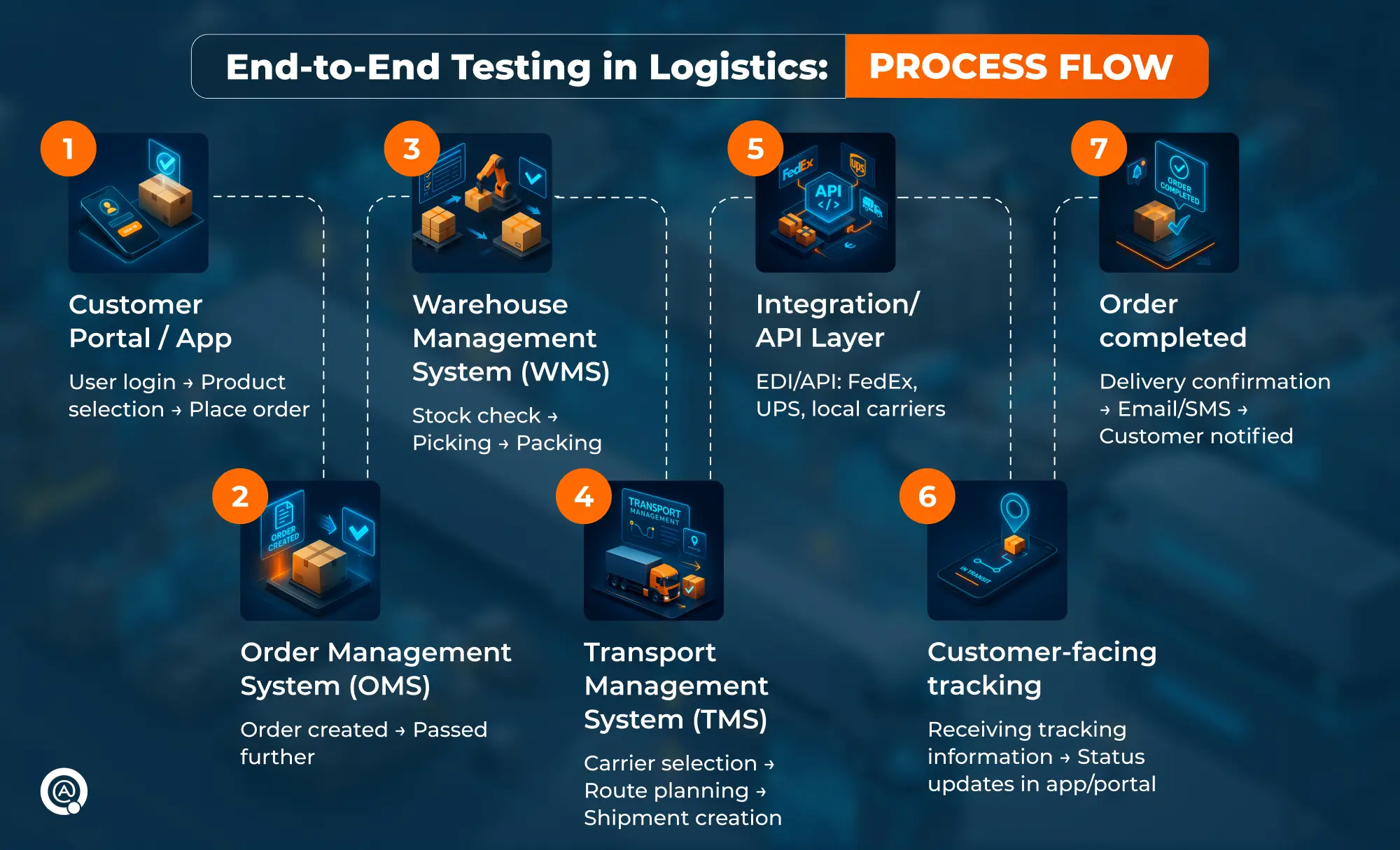

E2E testing verifies the entire logistics process flow, ensuring that all components — applications, databases, APIs, third-party services, and user interfaces — work together as intended.

Unlike unit or UI-only testing, E2E testing reflects real business scenarios, simulating how an order moves through the system until it reaches the customer. I find it most valuable that it shows how the product behaves in real conditions.

A typical process involves:

- Order management systems (OMS) for initiating and tracking requests.

- Warehouse management systems (WMS) for stock, picking, and packing.

- Transport management systems (TMS) for routing and carrier selection.

- APIs and EDI connections with external providers like FedEx, UPS, or regional carriers.

- Customer-facing portals and mobile apps for shipment tracking.

To avoid this domino effect, testing must validate every connection. It ensures:

✔︎ Data consistency across systems.

✔︎ Accuracy of routing and delivery timelines.

✔︎ Correct real-time updates to customers and partners.

✔︎ Resilience against network failures, unexpected user actions, and system load.

To see how this works in practice, let’s break down the key areas of logistics that require thorough end-to-end checks.

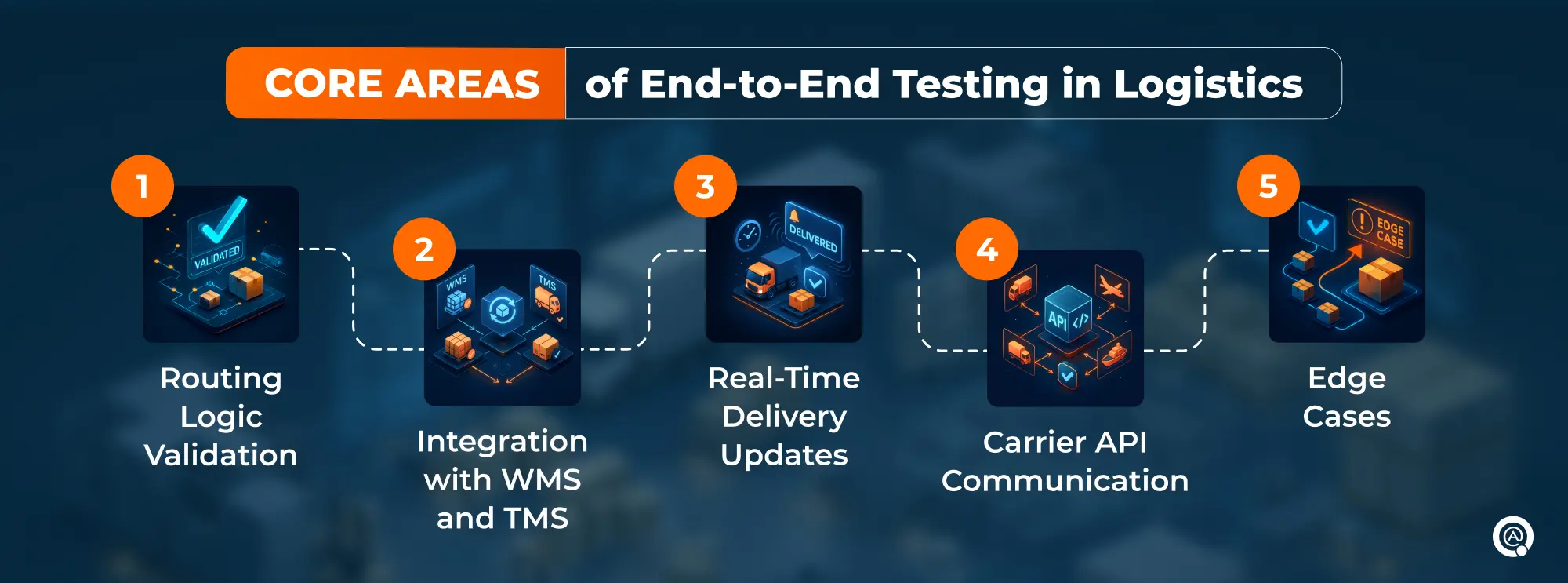

Core Areas of End-to-End Testing in Logistics

1. Routing Logic Validation

Routing errors can lead to costly delays. E2E tests must confirm that:

- Routes follow defined business rules (priority orders, delivery windows, restricted zones).

- Exceptions (road closures, carrier limits) trigger fallback routes.

- Optimizations, such as load balancing, are calculated correctly.

In practice: Assign a shipment to a restricted zip code for delivery. The system should reroute to an authorized carrier instead of failing.

2. Integration with WMS and TMS

Integrations are at the heart of logistics software. Testing ensures smooth communication between warehouse operations and transport planning.

- Inventory levels are updated in real time.

- Picking and packing confirmations trigger shipment scheduling.

- Delivery updates flow back into the WMS.

In practice: An order is picked and packed but not updated in TMS. The test must detect the missing update to avoid “phantom shipments”.

3. Real-Time Delivery Updates

Customers expect transparency. A single missed update can erode trust.

- Status changes (picked up, in transit, delayed, delivered) must synchronize across all systems.

- Notifications must be triggered instantly and accurately.

In practice: Simulate network latency between the carrier API and the logistics platform. Verify whether the system retries, queues, or fails gracefully.

4. Carrier API Communication

Carrier APIs differ in protocols, authentication, and error handling. E2E testing checks:

- Stable connectivity and retry logic.

- Proper parsing of API responses.

- Error handling for invalid or delayed responses.

In practice: Send a malformed request to a carrier API. The logistics platform should log the error and retry using the correct data.

5. Edge Cases

Real-world logistics is full of exceptions. Common edge cases to include in test suites:

- Order cancellation after shipment is prepared.

- Partial deliveries when some items are unavailable.

- Failed deliveries due to customer rejection or payment issues.

- Returns and reverse logistics for damaged or unwanted items.

In practice: Without testing these cases, the system may appear stable under “happy path” conditions but fail when reality hits.

Why UI Testing Alone Falls Short

A polished UI can create the illusion of correctness while the back-end is inconsistent. It’s one of the most common pitfalls in logistics software:

➡︎ Everything seems fine, but the underlying systems are out of sync.

- The UI may show “Delivered,” but the database still marks the order as “In transit”.

- Customers may receive a confirmation email, while the carrier has never picked up the parcel.

- A tracking page may display the right status, but the warehouse system hasn’t updated stock, creating discrepancies for the following order.

These mismatches directly affect operations, reporting, and customer trust.

UI testing ≠ system validation.

Only E2E testing, with database checks and integration monitoring, can confirm that what the customer sees truly reflects the system’s state.

Case in Point: Freight Transport Management Platform

One of our recent projects involved a freight transport management platform with two critical components: a dispatcher web application and a driver mobile application.

The business goal was to launch an MVP in just two months without formal requirements but with high expectations for stability and real-time performance.

Our QA team built complete test documentation and covered dispatcher–driver flows with end-to-end scenarios: task assignment, route synchronization, and delivery status updates. To support future releases, we also introduced regression automation with Appium for the mobile part.

As a result, the platform went live on time with zero critical defects. Post-launch, it successfully processed over 500,000 delivery tasks, and regression time was reduced by nearly 90%, enabling fast and confident updates.

This case highlights how end-to-end testing ensures consistency across multiple systems and devices, prevents data mismatches, and supports long-term product scalability.

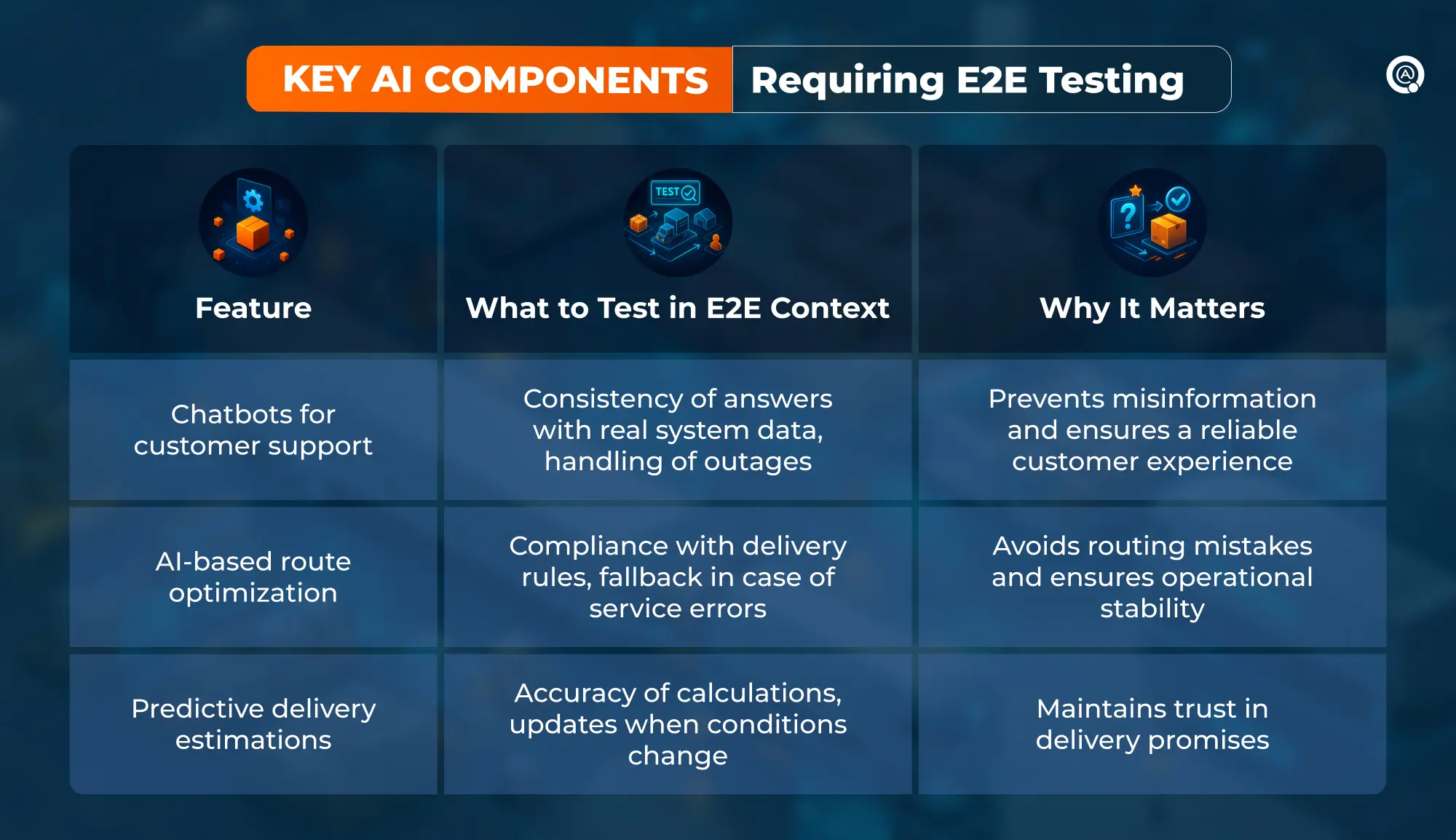

AI and Chatbots in Logistics Software

Modern logistics solutions often include AI assistants and chatbots. These tools provide quick access to delivery information, support operational planning, and introduce new testing requirements.

From our perspective, AI features cannot be tested in isolation. They must be validated in the logistics workflow to ensure alignment with WMS, TMS, and carrier systems.

This includes checking how they interact with real-time status updates, handling incomplete or delayed data, and how the system behaves if the AI component is unavailable. Testing can only confirm that AI modules add value without introducing new risks by covering these aspects.

Best Practices for E2E Testing in Logistics

- Test across environments: staging, pre-production, and live-like testbeds.

- Automate regression suites for repetitive flows (API checks, routing rules).

- Include negative scenarios: simulate network outages, invalid data, and API downtimes.

- Use monitoring and logging: ensure failures are detected, not hidden.

- Collaborate with business teams: QA must align with operational priorities, not just technical flows.

Conclusion

In logistics, every second counts and every update matters. End-to-end testing ensures that the entire ecosystem — from warehouses to carriers, from APIs to mobile apps — works together under real-world conditions.

It goes beyond UI checks, covering routing logic, integrations, delivery updates, carrier communication, and edge cases. With the rise of AI and chatbots, E2E testing becomes even more critical to maintain reliability and customer trust.

If this resonates with you, reach out to our experts — we’ll help run a tailored QA estimation for your logistics platform and show you how E2E testing can strengthen your operations.

Learn more from QATestLab

Related Posts:

- When Bugs Tank Your Rankings: How QA Testing Drives SEO Performance

- ICE Barcelona 2026: Between Poker Wins and Talks on QA in iGaming

- The 2025 Cloudflare Outage: A Stress Test for SaaS Resilience

About Article Author

view more articles